An in-depth look at the components of an omnidirectional diaphragm-style microphone capsule.

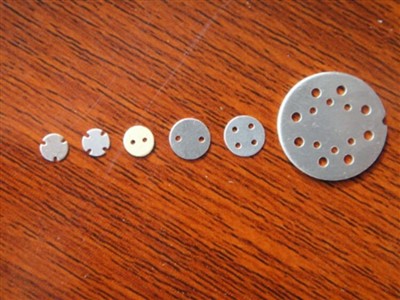

1. Dust-Proof Mesh

The dust-proof mesh protects the microphone by preventing dust from reaching the diaphragm. It also safeguards the diaphragm from external punctures and provides short-term water resistance.

2. Housing

The housing serves as the structural support for the entire microphone. It encapsulates other components, acts as the grounding point for the microphone, and provides electromagnetic shielding.

3. Diaphragm

The diaphragm is the primary sound-to-electrical conversion component. It is a stretched Teflon plastic film mounted on a metal circular ring. The surface in contact with the metal ring is coated with a thin layer of metal. The diaphragm can hold an electric charge, functioning as one plate of a variable capacitor and is capable of vibration.

4. Spacer

The spacer maintains the distance between the two capacitor plates, providing a gap that allows the diaphragm to vibrate and thus change the capacitance.

5. Backplate

The backplate forms the other electrode of the capacitor and connects to the gate (G) terminal of the FET (Field-Effect Transistor).

6. Copper Ring

The copper ring connects the backplate to the gate (G) of the FET. It also serves as a structural support element.

7. Cavity

The cavity secures the backplate and diaphragm ring, preventing them from short-circuiting with the housing or between the source (S) and gate (G) terminals of the FET.

8. PCB Assembly

The PCB assembly houses components such as the FET and capacitors. It also provides structural support for other parts of the microphone.

9. PIN

Some microphones feature pins on the PCB, allowing connection to other PCBs via soldering. The design may vary slightly between front-electrode and back-electrode styles.