MEMS Microphone

MEMS microphones are microphones produced using microelectromechanical system processing technology. MEMS microphones are also commonly referred to as microphone chips, silicon microphones, which are effectively etched into semiconductor silicon wafers. The pressure-sensitive removable membrane (septum) is etched behind the fixed perforated plate. The perforated retaining plate and diaphragm work together to form a capacitor (much like the design of a condenser microphone). Like most MEMS technologies, MEMS microphones are manufactured on the production line using semiconductor silicon wafers and highly automated processes. Different layers of different materials are stacked on top of the silicon wafer and then etched away the unwanted material. Once etched is complete, the transducer element of the MEMS microphone has a movable diaphragm, a fixed but perforated plate, and a surrounding enclosure. ASICs (application-specific integrated circuits) are designed to work with the transducer elements of MEMS microphones. It uses a charge pump to place a fixed charge between the fixing plate and the microphone film. ASICs are specialized microchips.

Advantages of MEMS Microphone

Size matters

MEMS microphones are incredibly compact, making them

suitable for applications where space is limited.

They are commonly used in smartphones, tablets, and

wearable devices, where miniaturization is critical.

Power efficiency

These microphones consume minimal power, which is

crucial for portable devices with limited battery

capacity. This ensures extended battery life for

your gadgets.

High-quality sound

Despite their small size, MEMS microphones offer

impressive audio quality, with excellent sensitivity

and signal-to-noise ratios. This makes them ideal

for capturing crisp and clear sound.

Durability

MEMS microphones are rugged and less prone to damage

from mechanical shock or vibration, making them

suitable for harsh environments and industrial

applications.

High reliability

MEMS reliability outperforms that of a similar

system assembled from discrete components. Because

of their small size and weight, MEMS mechanical

assemblies perform better in vibration and impact

conditions.

Low cost

The low cost of MEMS-based devices and MEMS scanning

mirror can be attributed to their high

processability and the ability to design using

commercially available functionally finished

components.The range of MEMS applications is

constantly expanding. Some of them are already

visible, most notably on smart roads, where MEMS are

embedded in the pavement to monitor its condition.

Why Choose Us

Quality assurance

In terms of quality assurance, the company strictly follows the standards and norms of the industry quality system. Adopt industry-leading testing equipment to ensure product quality and good reputation.

Professional service

We can accept factory inspection and goods inspection at any time. Technical discussion, research and development of new products, and complete after-sales service.

Cheap price

We have a professional purchasing team and costing team, trying to reduce costs and profits, and provide you with a good price.

Oem/odm

When you put forward your needs, our engineers will provide you with faster and more perfect customized solutions. We have a wide range of products, and we will provide technical support according to your actual needs to choose the right product for you.

MEMS Microphone Output Interface Category

Analog Single-ended

This is a commonly used format, and the price is usually lower

than the Differential type. The sensitivity is generally in

the range of -38dBV ~ 40dBV. All the audio codec microphone

inputs support this signal and make it the most popular one.

But when designing the PCB circuit for this kind of

microphone.

Analog differential-ended

This type is uncommon, and the price is usually higher than

Single-ended. It is a Differential Output. Therefore, the

sensitivity will also increase by 6dBV. The sensitivity is

generally set around -32dBV, and it can also increase the AOP

(Acoustic Overload Point). Most audio codec microphone inputs

also support this signal.

PDM (Pulse Density Modulation)

It is the main output interface of a digital MEMS microphone.

The L/R channel shares the Data BUS, so it only needs four

lines to complete the stereo L/R channel transmission; it is

also suitable for the PCB layout design of portable devices.

I2S (Integrated Internship Sound)

This digital audio serial bus standard format was developed by

Philips to transmit audio data between digital audio devices.

The bus is used explicitly for data transmission between audio

devices, widely used in various multimedia systems. Most

entry-level MCUs don't support PDM interfaces but basic

I2S interfaces. Therefore, some microphone manufacturers have

still launched I2S MEMES microphones for applications without

an audio codec.

TDM (Time-division multiplexing)

It divides the usage time of the transmission medium several

fixed time slots. Each time slot occupies a short period (for

example, 20ms) and is considered a virtual channel. When data

are communicated, the two interconnected parties will be set

to transmit data in a particular time slot. It has the right

to use the transmission intermediary for a specific time. For

a longer time, the entire transmission intermediary is the

same as having multiple connections, and they send data

simultaneously.

Application of MEMS Microphone

Smart home devices

MEMS microphones are integrated into smart speakers, virtual

assistants, and home automation systems. They enable voice

commands, allowing users to control lights, thermostats, and other

smart devices with spoken instructions.

Security systems

MEMS microphones are used in security cameras and surveillance

systems. They capture audio to enhance video footage, providing

valuable context for security personnel. Advanced models can

detect specific sounds, such as breaking glass or alarms,

triggering appropriate responses.

Medical devices

In medical applications, MEMS microphones are utilized in devices

like hearing aids and assistive listening devices. They improve

sound clarity, enhancing the hearing experience for individuals

with hearing impairments.

Industrial automation

MEMS microphones are used in industrial settings to monitor

equipment and detect abnormalities. They can detect unusual sounds

or vibrations in machines, indicating potential issues that

require maintenance or repair.

Consumer electronics

MEMS microphones are integral components of consumer electronics,

such as digital cameras and camcorders. They capture high-quality

audio during video recording, ensuring the recorded content is

immersive and engaging.

Gaming accessorie

MEMS microphones are used in gaming peripherals like headsets and

microphones. They capture clear voice communications during online

gaming, enabling players to strategize and coordinate effectively.

Educational tools

MEMS microphones are incorporated into educational devices and

language-learning tools. They facilitate interactive learning

experiences, allowing students to engage in language practice and

pronunciation exercises.

Iot devices

MEMS microphones are used in various connected devices in the

internet of things (iot) ecosystem. For example, they can be

integrated into smart appliances to receive voice commands, making

these appliances part of the smart home network.

Navigation systems

MEMS microphones are utilized in navigation devices for capturing

spoken instructions. They enhance the user experience by providing

voice-guided directions, mainly when visual guidance is limited or

unsafe, such as while driving.

Comparing MEMS Microphones and Electret Condenser Microphones

MEMS Microphones

Pioneering Miniaturization and Precision

MEMS microphones excel with compactness, integrated PCBs and

ADCs, low impedance for noise rejection, resilience to

vibrations, and continuous advancements, making them ideal

for space-constrained applications demanding high-quality

audio capture.

Electret Condenser Microphones

Versatility and Legacy Appeal

ECMs remain valuable for legacy integration, diverse

connectivity options, environmental resilience, directional

flexibility, and voltage tolerance. They are preferred for

seamless upgrades and backward compatibility and excel in

various scenarios with established designs.

The choice between MEMS microphones and ECMs depends on the application's precise demands, legacy systems, and environmental considerations. MEMS microphones offer compactness and high performance, while ECMs provide versatility and compatibility with established designs.

Components of MEMS Microphone

Diaphragm

Located on top of the microphone, is a very thin film, usually made of metal or ceramic material. The diaphragm vibrates with the fluctuations of the sound.

Backplate

Located underneath the diaphragm, it is usually made of solid material. There is an electrode on the backplate that senses the vibration of the diaphragm.

Air Gap

A tiny gap between the diaphragm and the backplate, in which the diaphragm will vibrate when the sound fluctuates.

Support structure

A stable frame structure used to support the diaphragm and backplate.

Inductor

An electronic device located on a support structure that measures the vibration of the diaphragm and converts it into an electrical signal.

How to Choose a MEMS Microphone

Power consumption

Power consumption is one of the most critical design

considerations, especially for portable and handheld electronic

devices. Therefore, the selection of power-efficient MEMS

microphones is crucial. Compared to conventional microphones, MEMS

microphones consume less power because all the circuitry is housed

in a single IC package. Moreover, analogue MEMS sensors consume

less energy than digital ones because of fewer stages.

Dimensions

The microphone size is another important consideration in the

design of modern portable electronic devices. Electronic gadgets

are shrinking daily, and available space is quite limited. MEMS

microphones are excellent in this regard because of their small

form factor. Due to this reason, manufacturers use these

microphones in tablets, mobile phones, smartwatches, and other

portable devices.

Noise floor

Noise, EMI, and buzzing are the biggest challenges in

high-frequency electronic circuits. Distortion in output signal

can lead to erroneous results and poor quality. The amount of

noise in the output signal in a quiet environment is known as the

microphone’s noise floor. Noise levels directly impact the

SNR of the microphone. Analogue microphones are more susceptible

to noise than digital microphones. MEMS microphones feature

on-chip signal conditioning circuitry to minimize noise and

interference.

Distortion

Total Harmonic Distortion (THD) is the deviation of a signal from

its actual waveform. Signal distortion in an audio system can

cause poor sound quality and user experience. The most common

cause of signal distortion is various types of noise and

interference.

Frequency response

Frequency response is the variation in microphone sensitivity at

different frequencies. The typical frequency range within which

MEMS sensors operate satisfactorily lies between 100Hz and 10 kHz.

As a result, high-performance MEMS microphones provide a flat

frequency response over the entire audible range, i.e. 20 Hz to 20

kHz.

Power supply rejection

PSP is another critical factor in the selection of MEMS

microphones. The ability of the microphone to reject the power

supply noise is known as PSR. In poor-quality microphones, the

power supply noise often appears at the output signal, which

causes distortion and sound quality issues.

Directionality

Board-level microphones can either be omni or uni-directional.

Uni-directional microphones can only gather sound from a

particular direction, while omnidirectional microphones can

receive sound from any direction. Therefore, the directionality of

a microphone is a crucial factor in its selection for a specific

application.

MEMS microphone contains both electronic and mechanical components on the same semiconductor wafer. It has a transducer and an application-specific integrated circuit (ASIC) integrated into a single component protected by a mechanical cover. A small hole on the cover or the base PCB allows the sound into the microphone. It is either top-ported or bottom-ported, depending on whether the hole is in the top cover or the PCB.

The image below shows that it consists of a micro-sized pressure-sensitive diaphragm transducer and signals conditioning pre-amplifier circuitry. In addition, the Digital version of the MEMS sensor has a digital converter to convert the analogue signal to a digital signal.

The micro-sized pressure-sensitive diaphragm acts as a

single plate of a capacitor. The ASIC-based charge pump

circuit injects charge between the capacitor plates.

The diaphragm movement due to sound pressure changes the

capacitance, which in turn causes the generation of an

electrical signal. This electrical audio signal is then fed

to the pre-amplifier.

An impedance converter reduces the output impedance of the

signal to something usable before feeding into the

amplifier.

What Are the Trends and Development Directions of MEMS Microphone in the Market

Higher SNR

MEMS microphone performance continues to improve. SNRs have

increased from 55 – 58 dB a few years ago to 63 – 66

dB today, resulting in cleaner audio capture and allowing

microphones to be used at greater distances with the same level of

clarity. High SNR levels are needed by automatic speech

recognition algorithms to achieve good word accuracy rates.

Higher sound pressure levels

Many microphone users are also requesting higher acoustic overload

points to prevent distortion in loud environments. Distortion

caused by clipping at sound pressure levels above the acoustic

overload point can make recordings made in loud environments such

as rock concerts unusable.

Smaller package sizes

MEMS microphone package sizes are also shrinking as consumer

demand for thinner, lighter products continues to increase. Early

MEMS microphones had package sizes of 3.76mm x 4.72mm x 1.25mm

while today 3mm x 4mm x 1mm and 2.95mm x 3.76mm x 1mm packages are

common. Newer MEMS microphones are available in 2.5mm x 3.35mm x

0.98mm and 2.65mm x 3.5mm x 0.98mm packages. This trend is likely

to continue, although smaller microphone packages make it more

difficult to maintain or improve audio quality due to the

shrinking size of the microphone’s back chamber.

Ambient noise reduction

Many smartphones and tablets are starting to use more than one

microphone to enable features such as video recording. Another

common way in which multiple microphones are used is for ambient

noise reduction. Many smartphones use a microphone located on the

top or the back of the phone to detect noise in the surrounding

environment and subtract it from the output from the voice

microphone(s) to help improve intelligibility. Microphones whose

primary purpose is video recording are frequently also used for

ambient noise reduction.

Tighter control of sensitivity

The performance algorithms used to perform functions such as noise

cancellation and beamforming usually assume that the sensitivity

of the microphones being used is the same, so variations in

sensitivity between the microphones in an array hurt the

performance of the algorithms.

Company Profile

Shenzhen Marquess Electronics Co., Ltd. was founded in July 2004, originating from the Japanese AOI Electric Motor Manufacturing Company as a joint venture specializing in the production of ECM (Electret Condenser Microphones).

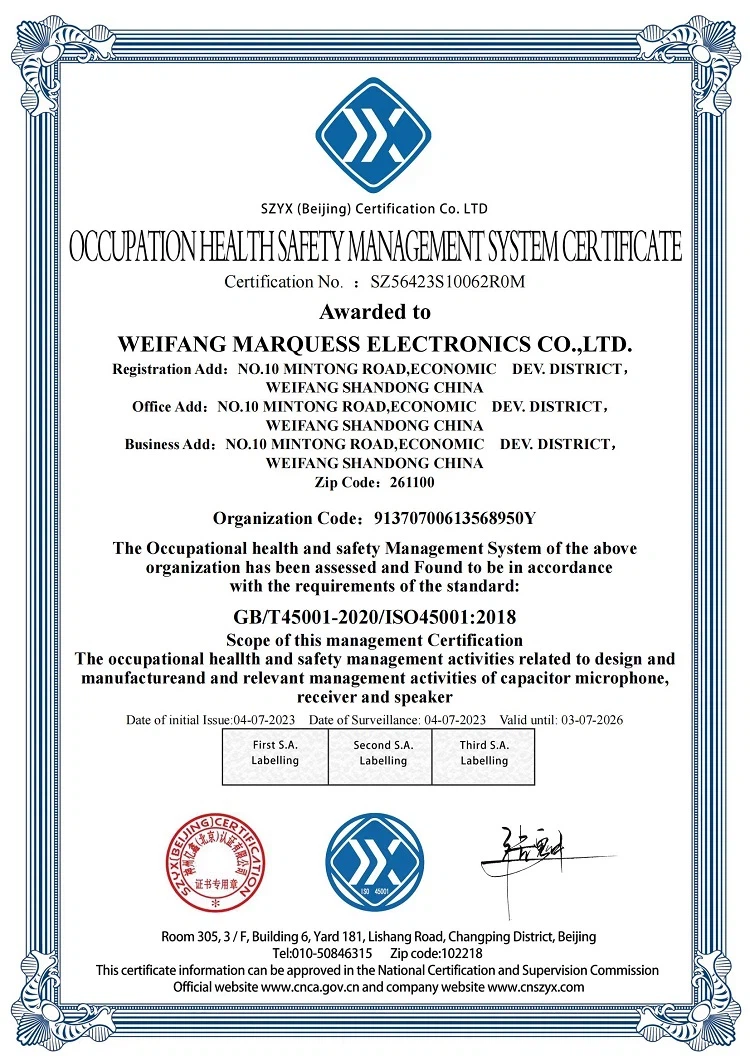

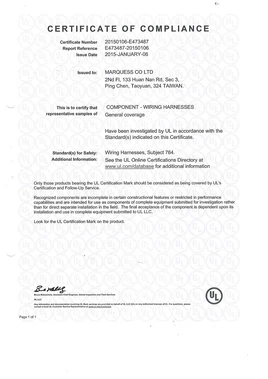

Our Certificate

ISO 9001 2015,ISO 14001 2015,ISO 4500 12018,UL E473299,UL E473487

FAQ

Q: What is a MEMS Microphone?

Q: How does a MEMS Microphone differ from traditional microphones?

Q: What are the advantages of using a MEMS Microphone?

Q: In what devices are MEMS Microphones commonly found?

Q: Do MEMS Microphones require phantom power to operate?

Q: Are MEMS Microphones more durable than traditional microphones?

Q: Can MEMS Microphones capture high-quality audio recordings?

Q: What is the frequency response range of MEMS Microphones?

Q: Are MEMS Microphones suitable for voice recognition and voice control applications?

Q: Do MEMS Microphones offer noise-canceling features?

Q: Can MEMS Microphones be used for recording music and instruments?

Q: Do MEMS Microphones require special handling or maintenance?

Q: Are MEMS Microphones sensitive to environmental factors like humidity and temperature?

Q: What is the typical signal-to-noise ratio (SNR) of MEMS Microphones?

Q: Can MEMS Microphones be integrated into wearable devices?

Q: Do MEMS Microphones offer multiple polar patterns like traditional microphones?

Q: What is the power consumption of MEMS Microphones compared to traditional microphones?

Q: Are MEMS Microphones cost-effective compared to traditional microphones?

Q: Can MEMS Microphones be used for teleconferencing and video calls?

Q: What advancements can we expect in MEMS Microphone technology in the future?